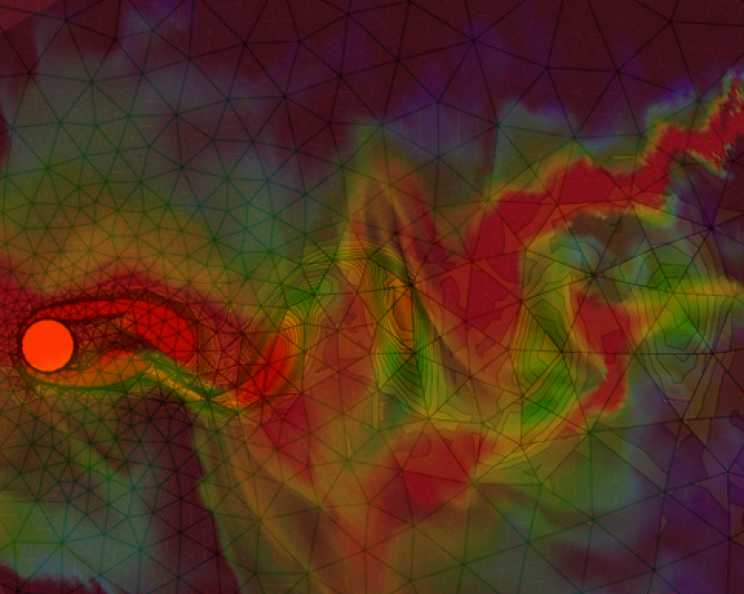

Computational Fluid Dynamics (CFD) modelling provides a powerful tool for engineers to analyse and optimize airflow in various applications, from HVAC systems to aerodynamics in vehicles and buildings. CFD modelling offers several benefits for studying airflow:

- Cost-Effectiveness: CFD allows engineers to simulate airflow digitally, reducing the need for expensive physical prototypes and testing. This can significantly lower development costs.

- Time-Efficiency: CFD simulations can be conducted relatively quickly compared to physical testing, allowing for rapid design iterations and faster product development cycles.

- Detailed Insight: CFD provides detailed insights into airflow behaviour, including velocity, pressure, temperature distributions, and turbulence characteristics. This information is often challenging or impossible to obtain through experimental means.

- Design Optimization: By analysing CFD results, engineers can optimize designs to improve airflow efficiency, reduce drag, enhance heat transfer, and minimize energy consumption.

- Risk Reduction: CFD can help identify potential airflow problems early in the design process, reducing the risk of costly errors or performance issues in the final product.

- Environmentally Friendly: Using CFD to optimize airflow can lead to more energy-efficient designs, reducing environmental impact and operating costs over the product"s lifecycle.

Contact details:

Contact details: